Laser bonder

Curtain up for a completely new technology

With the world premiere of the laser bonder in 2015, F & K DELVOTEC GmbH once again proved the validity of its motto: Staying ahead in Bonding Technology.

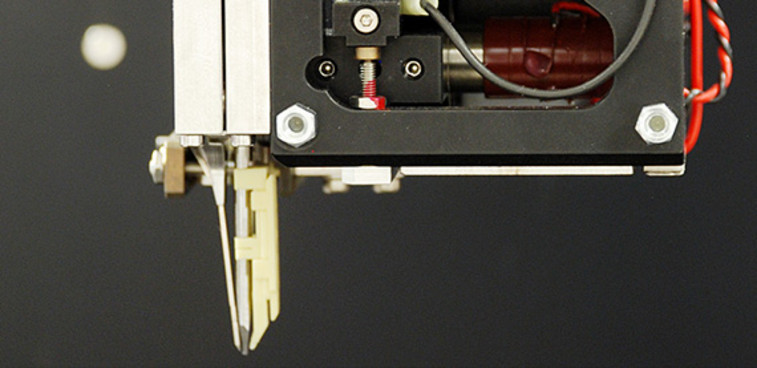

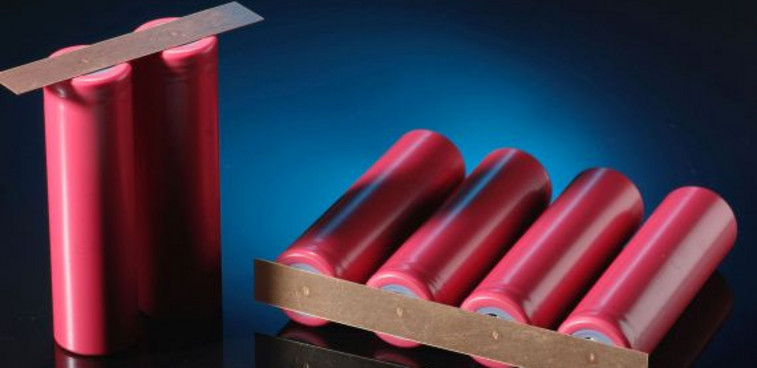

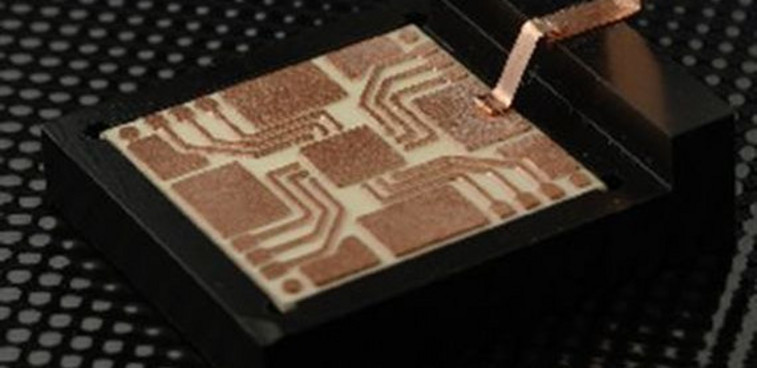

The completely new process based on laser microwelding is particularly suitable for joining thick bonding wire on battery terminals and on DCB substrates and copper terminals in power electronics module housings. Using laser bonders, the application range of ribbon bonding is opened up for even higher currents.

Bonding using laser radiation

In power electronics, wire bonding eventually reaches its physical limit in terms of transmittable currents. Laser welding, on the other hand, can contact cables of almost any thickness, but is less flexible due to the prefabricated connectors required.

In close cooperation with the Fraunhofer Institute for Laser Technology (ILT) and S&F Systemtechnik, F & K DELVOTEC therefore developed a technology that combines the best of both worlds as part of the joint project RoBE (Robustness for Bonds in E-Vehicles), funded by the German Federal Ministry of Education and Research (BMBF): laser bonding.

Robust process enables simple and cost-effective electronics production

With the contacting of aluminium and copper wires on DCB substrates and copper terminals in power electronics, laser bonding not only offers a wider range of applications for bonding technology, it is also more robust than conventional wire bonding.

The demands on surface quality and cleaning processes are lower, and at the same time the vibration-free nature of the workpiece is no longer the bottleneck for zero-defect production. In the field of battery technology, too, battery terminals can be contacted reliably and flexibly in this way. The handling of connector plates is thus completely eliminated.

The advantages

- Extended application range for precise and reproducible joining of copper or aluminium wire.

- Processing of connectors and bonding wires with diameters up to 500 μm

- Robust manufacturing process

- Reduced demands on surface quality, cleaning processes and freedom from vibration of the workpiece than with wire bonding

- Bonding on new surfaces and with new materials