Leader in Innovative Joining Technology

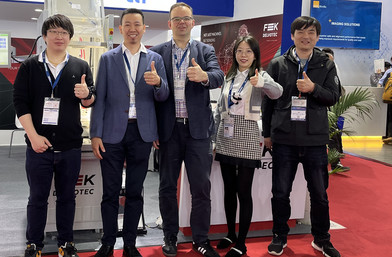

Since 1978, F & K DELVOTEC GmbH has played a decisive role in shaping the innovation landscape in the field of ultrasonic bonders. Its groundbreaking developments have had a decisive impact on the market and position the company as an innovation leader. Through an exceptionally high focus on research and development as well as close cooperation with leading companies and renowned research institutes, top performances have been achieved.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/a/csm_Diode_e4b1145801.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/c/d/csm_Diode_Laser_92dfa8f127.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/f/b/csm_Hybrid_77d3783274.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/2/csm_Leiterplatte_309c6b5319.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/c/6/csm_Kondensator_a9960e9e92.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/f/0/csm_PCB_e84a218822.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/6/csm_Gussgehaeuse_78e219246f.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/3/4/csm_Batteriemodul_8c4f3e0c2c.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/0/8/csm_US_FW_AI_25-50_cc9a66a164.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/d/4/csm_US_FW_Cu_25-50_728081fe88.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/0/csm_US_FW_Au_25-50_c3fe02f494.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/f/6/csm_US_BW_AU_25-50_5ae35ac0c9.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/0/0/csm_US_BW_HA_AU_25-50_fe531523b2.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/d/c/csm_US_HW_AI_125-375_86a2de2982.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/e/a/csm_US_HW_AI_375-500_895d7a10ea.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/3/4/csm_US_HW_Cu_125-375_876d0029b1.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/0/0/csm_US_HR_AI_0-2_100-300_6f345c89da.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/8/5/csm_US_DA_AI_Au_25-50_50-300_40434b1fee.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/c/1/csm_L_Simpl_Low_Ind_Cu_300-800_b69d5a5cce.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/4/b/csm_L_RIBBON_Cu_1-2_50-300_14ab8041b2.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/8/d/csm_L_RIBBON_AI_1-5_100-500_eaf6bd57c6.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/3/2/csm_L_PCB_UNSUPPORTED_AI_Cu_1-2_9e168aa7cb.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/f/3/csm_L_FLEX_PCB_RIBBON_Ni_w1_60-375_10917d8199.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/3/csm_L_TAB_AI_0_5-2_ff0eee1aa1.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/3/a/csm_L_TAB_Cu_50-300_a40ddc7cc7.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/2/d/csm_L_TAB_Cu_300-800_ff6c8ac525.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/3/csm_L_TAB_21_Cu_500-300_a54809a4a0.png)